What Is a Calorimetric Flow Sensor?

Calori... what? Though it may sound like counting calories, calorimetry is actually a principle of measurement based on the fact that heat is dissipated by a flowing medium. The word calorimetry derives from the Latin words calor, for warmth, and metrum, for measure. The sensors can also be referred to as thermal flow sensors.

In many applications, the flow sensor has to be non-invasive or minimally invasive, so that there are no dead spaces. This is especially true for hygienic applications, since dead spaces pose a risk of contamination and can also be difficult to clean. A lack of dead spaces also means that the pressure drop is negligible.

Calorimetric sensors can be divided into calorimetric flow monitors and calorimetric flow meters. Flow monitors can be set to a threshold value and configured to emit an alarm when the flow falls below or exceeds this value. Calorimetric flow meters can provide a specific reading.

There are two different methods of measurement: the heating method and the hot wire method.

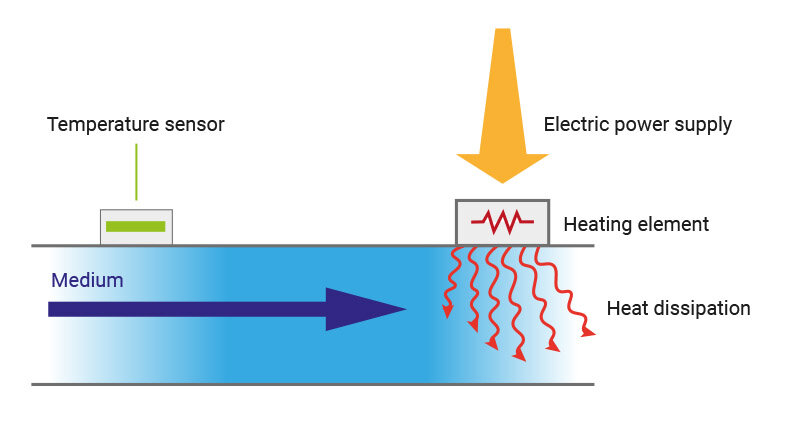

The heating method requires two temperature sensors and one heating element, e.g. a wire winding. Power is supplied to the heating element to produce a constant heat output. One of the temperature sensors measures the temperature directly at the heating element. The other measures the fluid temperature. The difference is the amount of heat that is dissipated. If we know the thermal capacity of the medium to be measured, we can derive the flow rate.

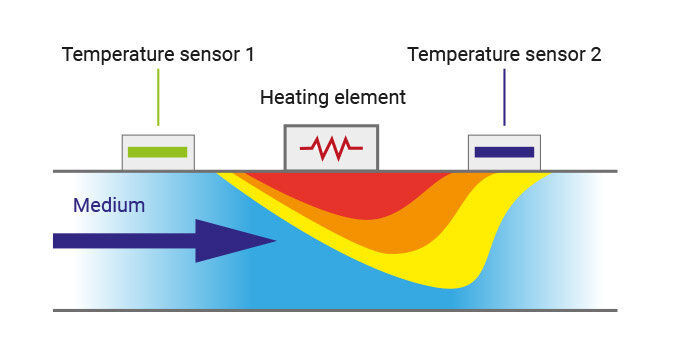

Alternatively, the heating element can be mounted equidistant from the two sensors. If there is no flow, the temperature distribution will be symmetrical. Once the medium starts flowing, this temperature distribution is distorted, thus resulting in a flow-dependent temperature difference. The advantage of this arrangement is that it enables you to measure in both directions and detect the direction of flow.

With the hot wire method, a thin wire is heated by an electrical current. The temperature is set to a constant value. The higher the mass flow rate, the greater the amount of heat dissipated and the more electrical energy must be supplied to keep the wire temperature constant. Since the heat dissipation also depends on the medium temperature, an additional reference temperature sensor is required.

Depending on their design, calorimetric flow meters are also suitable for measuring gases. With this method, the measurement result always refers to the mass flow. In most applications, however, we are interested in the volumetric flow. This is calculated as follows:

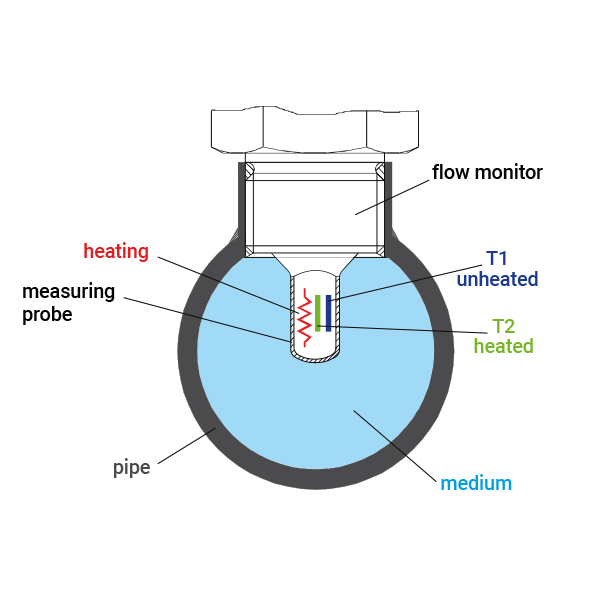

These sensors can be designed as a screw-in version with a probe, or as an inline version. The disadvantage of screw-in sensors is that the probe projects into the pipe cross-section. The advantage is that you can use one sensor for different nominal diameters.

There are also inline versions in which the heating element and the temperature sensors are mounted on the outside of the measuring pipe. This results in a completely non-invasive flow measurement.

As a rule, calorimetric flow meters are suitable for fluid temperatures of up to about 70°C. This upper limit is due to the fact that the heat dissipation is no longer sufficient at excessively high temperatures.

If this has piqued your interest, be sure to take a look at our calorimetric flow monitors. If you have any questions about this product, please get in touch.