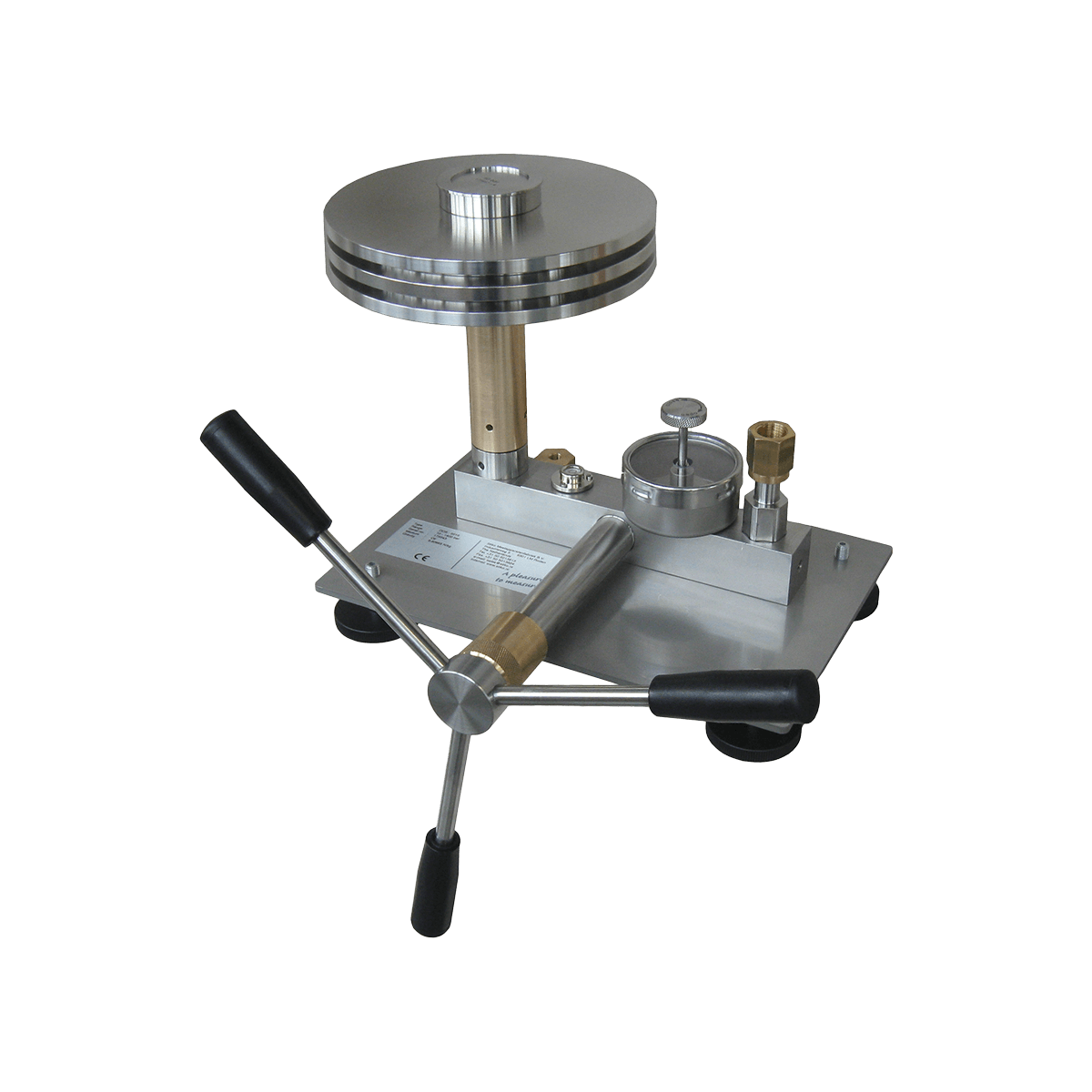

A deadweight tester is based on a high accurate manufactured piston and cylinder assembly. This cylinder is mounted in a column. The piston can rotate and move freely up and down. Accurate calibrated masses are loaded on top of the vertical mounted piston. A pressure is applied on the bottom of the piston to lift the piston with masses. This creates a balance between the force made my the masses (downwards) and the force made by the pressure (upwards) and the effective area of the piston cylinder assembly.

SIKA manufactures deadweight testers with an accuracy of 0.015 % of reading and are delivered with a SIKA calibration certificate which is traceable to national and international standards. Without additional costs they can be calibrated according to the local gravity instead of the standard gravity of 9.80665 N/kg. Also certification by a national or international accredited laboratory as DAkkS is available to additional costs. We recommend a recalibration every 2 to 3 years depending on the amount of use.

Deadweight testers are the basic primary standard used and its principle is worldwide accepted for the most accurate measurement of pressure. No other piece of equipment for pressure measurement can match the stability, repeatability and accuracy of the deadweight tester. It is ideal for calibrating pressure transducers, pressure gauges, transfer standards, recorders, digital calibrators, etc.and can also be used to measure directly the pressure in systems and processes where precise measurements are important.