For every application the right model.

Scroll down

Correct and reliable measurements are the precondition for all forms of high-quality industrial production. Measuring devices are used, amongst other purposes, for the quantitative determination of properties and for the purposes of control, regulation and automation in production, and form an important part of the industrial quality assurance. Pressure is a relevant process and production variable, the correct and reliable measurement of which can be of decisive importance.

In the production of foodstuffs, pharmaceuticals, and plastic components, for example, and in many other areas of industry, the correct pressure is critical to the quality of the product or the efficiency and safety of the production process. If plastic bottles are inflated with the incorrect pressure during production, for example, they will not hold. Steam boilers can explode if the safety valves are not working correctly. Pressure can only be measured correctly and always reliably with regular calibration. After all: Pressure gauges, pressure sensors, pressure switches, safety valves and general pressure devices of all types are subject to stress during their use, such as changing ambient conditions or aggressive measuring materials. This almost inevitably means that an (imperceptible) loss of measuring accuracy occurs over time, which is known as drift. This is where pressure calibration steps in.

In the event of pressure-sensitive production processes – in which pressure is a process-critical variable – regular pressure calibration is required, among other reasons, to prevent faults in the process sequence or safety risks.

What is pressure calibration?

Pressure calibration ensures that the deviation of the display value on the pressure measuring device (for example, a pressure gauge, pressure sensor, etc.) is known and can be taken into account for a correct measurement. For this purpose, the pressure measuring device to be calibrated and a calibrated reference pressure gauge which represents the standard value are exposed to the same pressure within a self-contained pressure system. The measured values are then compared and the deviations are documented in a certificate. The deviations determined by the pressure calibration can subsequently be put to use for adjusting the pressure measuring device. It should then be noted, however, that the calibration certificate is no longer valid because a change has been carried out. In this case, a new calibration is necessary for a valid certificate.

What devices can and have to be pressure calibrated?

In principle, each pressure measuring device is subject to drift over the course of time, which means it is possible that the specified and required measuring accuracy cannot be maintained.The deviation is determined during the calibration, and can also be used to determine the measuring accuracy. Pressure measuring devices have to be calibrated when the pressure that they measure is a process-critical parameter.

The benefits of pressure calibration

In addition to production requirements which require pressure calibration, other benefits result from the use of calibrated pressure gauges and pressure sensors: Reliable measurements and correct production pressures contribute to higher productivity, reduce the risk of unexpected production downtimes, provide the basis for the fulfilment of environmental requirements, and contribute to the optimising of profits thanks to a more efficient production.

Good reasons for pressure calibration

• High and consistent product quality

• Compliance with industrial standards and legal regulations

• Process optimisation and increased productivity

• Prevention of unexpected production downtimes

• Profit optimisation

How often do I have to calibrate my measuring equipment?

The frequency of calibration is a question of balancing the risks and costs. The shorter the time interval between two calibrations, the lower the risk of inaccurate measurements. It is often recommended that measuring instruments are calibrated once a year.

How are pressure gauges and pressure sensors calibrated?

The practical implementation of a pressure calibration only requires a few steps and can be completed in a few minutes. The pressure gauge to be calibrated or the corresponding pressure sensor - referred to as the device under test - is connected to the pressure calibrator either directly or via a hose. In principle, this pressure calibrator consists of a reference pressure gauge and a pump for the pressure build-up. For the calibration, the device under test and reference pressure gauge are subjected to the same pressure and compared with each other. The difference between the two display values is documented in a certificate. The calibration process is then complete. A subsequent adjustment of the device under test is possible, but the calibration certificate loses its validity as a result.

Commonalities and differences in calibrating pressures

Difference between pneumatic and hydraulic calibrators

As a rule, pressure calibrators can be divided into pneumatic and hydraulic versions according to the principle used for the pressure build-up. Pneumatic pressure calibrators use the ambient air as a calibration medium, while hydraulic calibrators work with oil, or, as is possible with certain SIKA pressure calibrators, using tap water. To generate the pressure in the pump body, force is required. For hand, lever or spindle pumps, this is provided manually by the user.

Commonalities of calibration procedures

All calibration procedures use the DUT (device under test), a measuring device for referencing purposes (REF) or a solid measure in order to determine the display deviation of the device under test. An adjustment can be made subsequent to the calibration procedure. The objective of this adjustment is to eliminate the deviation determined or, at least, to reduce it in such a way that the possible measurement inaccuracy is within a defined tolerance range.

Differences between calibration procedures

In addition to the calibrating medium and the associated pressure and application range, calibration procedures can be broken down into direct and indirect comparative procedures. In the case of direct comparative calibration procedures, a reference measuring device is used and the applied pressure is read from the reference device; in the case of indirect comparative procedures, a solid measure is used. Oil deadweight testers operate according to this principle. In this case, the reference pressure is determined by weights and the gravitational force.

Differences and areas of application of pneumatic and hydraulic pressure calibration procedures

Pneumatic and hydraulic calibrators not only use different calibrating media, they also have their own specific application. As pneumatic calibrators can generate a vacuum, they can also be used for calibration in the negative pressure range. The area of application of hydraulic systems, in contrast, starts at 0 bar rel. and extends far beyond the area of application of pneumatic systems with more than 1,000 bar. The calibrating medium is responsible for this. Hydraulic oil allows for a far easier build-up of high pressures than is the case with ambient air. Another factor in the choice of the correct pressure calibrator is the area of application of the device under test which is to be calibrated. In this respect, it is often the case that pressure gauges and pressure sensors must not be wetted or come into contact with hydraulic, aggressive or ionising substances, in the foodstuffs or pharmaceuticals sector, for example. For this purpose, pneumatic or hydraulic pressure calibrators, which can be operated with water, can be used. At over 1,000 bar, systems which work with hydraulic oil are recommended, as this allows for the more straightforward generation of the test pressure due to its higher viscosity.

SIKA quality standards in calibration instruments

We have had an accredited DAkkS laboratory for pressure since 1995, and since then we have also been a member of the German Calibration Service (DKD) and accredited according to DIN EN ISO / IEC 17025. We have been actively contributing our experience to working groups and regularly participating in ring comparisons for over 20 years.

Our pressure calibrators are designed and built according to the requirements of the German accreditation office DAkkS (Deutsche Akkreditierungsstelle GmbH), and guarantee long-term reliability and the highest quality. They therefore help our customers to ensure a consistent product and production quality. You are welcome to request that our pressure calibrators are delivered with a calibration certificate featuring the DAkkS accreditation symbol. As an official certificate, this provides unconditional traceability according to the national and international standards and is internationally recognised.

When is a DAkkS calibration certificate recommended?

DAkkS is responsible for the accreditation, monitoring and assessment of laboratories in accordance with DIN EN ISO/ IEC 17025. A pressure calibrator with a DAkkS calibration certificate is recommended:

• for exceptionally high-quality calibrations

• if international recognition is required

• if the full traceability of the calibration is required

• for the calibration of test equipment which is used as a standard for the testing of further test equipment

• for compliance with internal requirements

Pressure calibrators from SIKA Dr. Siebert & Kuehn

Development history of pressure calibration at SIKA

We have been developing and manufacturing pressure calibrators for 20 years, and specialise in hand-operated, transportable systems for the on-site calibration and inspection of pressure equipment. Today, we offer a complete range of pressure calibrators for a wide variety of applications in the range up to 1,000 bar as well as customer-specific designs, also for small unit volumes.

First/outstanding products

Until the early 2000s, pneumatic pumps were only available with a working range of up to 20 bar. In 2010, SIKA developed the P40, the first hand test pump configured for up to 40 bar. Later, a model with a working range of up to 60 bar followed: the P60.

Details concerning accuracy

A pressure calibrator consists of a pressure generator (hand pump, spindle pump, lever pump) with the associated reference pressure gauge. In the range -1 to 1,000 bar, SIKA offers products with various accuracies from 0.5% to 0.05% over twelve pressure stages.

General applications

With our hand test pumps and table top test pumps, the testing, adjustment and calibration of pressure sensors, pressure gauges, pressure switches, safety valves and pressure devices of all kinds is possible. Our pressure calibrators are optimised in terms of their function and use, and can be connected to all the standard pressure systems. We can also offer you specific adapters for special solutions.

Overview of the SIKA pressure calibrators

Our range includes both pneumatic and hydraulic pressure calibrators.

Pneumatic calibrators

Air is the ideal test medium, especially in applications in which the device under test must not be wetted or where aggressive or ionising substances may not be used. The pneumatic test pumps from SIKA fulfil requirements that other suppliers are frequently only able to cover with several products. Accordingly, the P40 and P60 allow for the direct switching between pressure and vacuum, pressure generation up to 60 bar, fine adjustments in the mbar range, and stable pressure conditions with a drop rate of a few mbar / minute.

Hydraulic calibrators

We have developed our easy-to-use hydraulic test pumps especially for the medium to high pressure range. With the built-in reservoir for the hydraulic fluid, they are also very mobile, and can be used on an exceptionally flexible basis with a measuring pressure of up to 1,400 bar. Our test pumps and pressure calibrators allow for the testing, adjustment and calibration of pressure sensors, pressure gauges, pressure switches, safety valves and pressure devices of all types.

Oil deadweight testers

The principle of this calibration system is based on the equilibrium between the forces simultaneously acting on a piston from above and below. Calibrated weights (the solid measure) generate a mechanical force from above, while pressure acts from below by means of hydraulic oil. If both forces are in equilibrium with each other, the piston in the cylinder begins to float and the required test pressure within the system is attained. The actual pressure shown on the device under test can now be read and compared with the required pressure in the system determined by the solid measure applied.

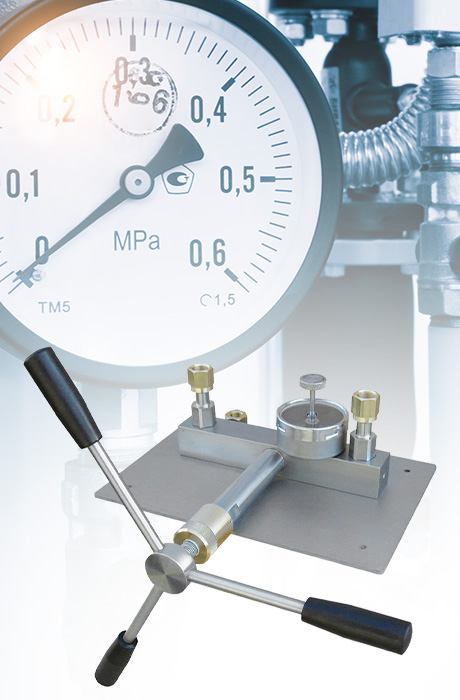

Hand test pumps – mobile, adaptive and independent

Lightweight, compact and easy to transport

Our pneumatic hand test pumps are lightweight, can be stored in any toolbox, and are easy to transport.

Adaptation to every measurement situation

Our hand pumps can be adapted to all the standard pressure systems quickly and easily by connecting them via a heavy-duty industrial pressure hose with quick coupling. An ultra-fine thread pitch and a large-volume regulating valve allow for precise adjustments in the mbar range, while the tool-free changeover allows for a rapid switch between overpressure and vacuum generation.

Independent of the electrical power and compressed air network

With their design and operation, our pneumatic hand test pumps do not require any additional supply voltage or any connection to a compressed air network. The wear-free pressure generation is straightforward and easy to operate, regardless of the ambient temperature during manual operation.

Extensive range of application

Our pneumatic hand test pumps are designed for mobile use on a comprehensive and in-depth basis, and cover every production time and process in the range up to 60 bar, from the assembly to the production, all the way through to the maintenance, quality assurance and repair. Our pneumatic hand test pumps are available in three versions of up to 4, 40 and 60 bar.

Ease of use

As the name suggests, the required test pressure is generated manually in our pneumatic hand test pumps with the use of the handles before being precisely set using the fine adjustment valve. This means that the same pressure level is applied to both the device under test and the reference instrument. The pressure can be reduced on a continuously adjustable basis using the pressure relief valve. This also guarantees a precise and simple test run when the pressure drops. Analogue and digital pressure gauges as well as hand-held instruments can be used as reference instruments.

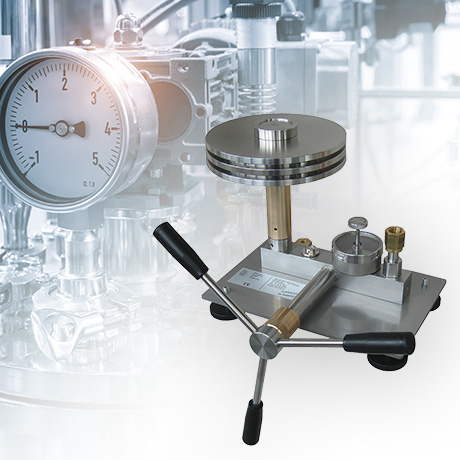

Table top test pump with spindle wheel

Accurate, also at maximum pressure

Our latest generation of table top test pumps guarantees precise measurements and a long service life, also at high pressures. All the parts that come into contact with the medium are made from stainless steel and guarantee wear-free operation.

Mode of operation

Our table top test pumps have a large base plate. This ensures a high degree of mechanical stability and allows for the straightforward assembly of the devices under test, including those with a large nominal diameter. The built-in adapters on the pressure connections also allow for the reference pressure gauge and device under test to be freely aligned. This means that almost every test situation can be taken into account.

Test medium

Depending on the model, both distilled water and hydraulic oil can be used as the test medium.

Easy operation

The filling of the pressure vessel and the generation of the test pressure take place on a very straightforward basis with a rotatable spindle. Due to the pressure medium reservoir, which is fitted to the test pump as standard, the charging of large volumes poses no problem. Pressure fluctuations due to air and gas components in the filling liquid, the compensation of thermodynamic effects, as well as an exact setting of the desired test pressure are carried out via the fine adjustment.

Table top test pump with lever

Compact on the outside, large on the inside.

Despite their compact design, our lightweight, high-pressure, hydraulic table top pumps have a large tank with a usable tank volume of 327 cm3. In combination with a delivery volume of 0.9 cm3 per piston stroke, they offer the possibility of testing several devices under test simultaneously.

Quick test set-up

The devices under test are mounted either directly on the pressure hose supplied or via a separate distributor block. This saves time and makes your testing task very efficient. The integral check valve in the pressure vessel ensures stable pressure conditions very quickly, while the built-in safety valve protects against overloads.

Oil deadweight testers

Our oil deadweight testers have a reading accuracy of 0.015% of the measured value. They come with either a SIKA calibration certificate which is traceable to national and international standards or a DAkkS calibration certificate. The deadweight testers can be adapted to the local fall acceleration instead of the normal fall acceleration of 9.80665 m/s² at no extra cost.

Accessories, service and spare parts

Our calibration devices are available with a transport case and adapter set. We can also provide you with any additional accessories and spare parts, such as seal kits, pressure hoses, inlet and outlet valves, fine adjustment and pressure relief valves or plate weights

for oil deadweight testers.

Reference pressure gauge - accuracy & characteristics

Our range includes a wide range of digital pressure gauges in several accuracy classes with a deviation ranging from 0.5% to 0.05%, from the bourdon tube pressure gauge through to the precision digital pressure gauge in industrial configuration. Those have characteristic properties. Accordingly, the digital configurations measure the pressure reliably in any position, while the analogue precision gauges have to be held vertically for exact measurements. Moreover, digital pressure gauges are insensitive to vibrations and have a higher reading accuracy and display resolution. All our digital reference pressure gauges are able to indicate the pressure in the units of bar, mbar, kPa, MPa, PSI and kg/cm².

Calibration service

Our calibration laboratory for the measurement of absolute pressure and positive overpressure offers every possibility for the calibration of analogue and digital pressure measuring devices, as well as pressure sensors with an electrical output signal such as 0...10 V or 4...20 mA. The calibration takes place as a comparative measurement against a piston pressure gauge which is used as a reference standard. With the piston pressure gauge, the calibrating object can be exposed to defined pressures in the range of 1...1,200 bar. Depending on the measuring range, the smallest possible measurement uncertainties are 0.7 mbar. A DAkkS calibration certificate is available to you upon request.

Sales

Have we sparked your interest? Our sales experts will be pleased to advise you individually, also on spare parts and accessories.

Service and after-sales

Our Returns Management team is responsible for processing all repair and calibration orders as well as complaints. In the event of returns, your contact in our sales team is your first point of call. Please use our RMA form in all cases. This allows us to process your request as quickly as possible and to keep you informed of the order status.