The Low-Down on Industrial Thermometers

Different types of mechanical measuring device are used for temperature measurements. Among the devices used particularly often are industrial thermometers and dial thermometers, in heating systems or on board ships, for example. This blog post discusses these two types of mechanical thermometer in detail. You will learn more about the history of the industrial thermometer, how industrial and dial thermometers work as well as the advantages of using them. You will also find out why industrial thermometers, unlike other measuring instruments, do not require calibration. This article also explains what you need to bear in mind when installing industrial thermometers and dial thermometers. Finally, we look at the question of why the use of these tried-and-tested mechanical measuring devices continues to be justified in the industrial world of today.

When and why was the industrial thermometer invented?

Which mechanical measuring principles are used in our thermometers?

How does an industrial thermometer work?

What are the advantages of the use of industrial thermometers?

How does a gas filled dial thermometer work?

What are the advantages of using a gas filled dial thermometer?

How does a bimetal dial thermometer work?

What are the advantages of using a bimetal dial thermometer?

What are the reasons for the calibration of measuring devices?

Why don’t industrial thermometers need to be calibrated?

How do we check the accuracy of mechanical thermometers?

What must be observed when installing industrial thermometers?

What must be observed when installing gas filled dial thermometers?

What must be observed when installing gas filled dial thermometers with capillary tubes?

What must be observed when installing bimetal dial thermometers?

How are industrial thermometers and dial thermometers installed in a system?

Why are industrial thermometers and dial thermometers still used?

Industrial thermometers, or more precisely, industrial glass thermometers with a V-shaped top section, were invented by SIKA.

Until their invention, for which we were awarded the patent in 1939, industrial thermometers with a round brass top section and a thin capillary on a scale were widely used. The capillary and the scale section were enclosed in a glass tube (known as an enclosed-scale thermometer). They were similar to the cooking thermometers that many people may remember from their youth.

As enclosed-scale thermometers were often susceptible to breakage, Hans Siebert (Dipl.-Ing.) developed a revolutionary design consisting of a solid material capillary rod. The scale was applied directly to the capillary rod and protected by a V-shaped casing. The measuring range was engraved on the scale side of the casing.

This design quickly proved to be very successful in the maritime sector, as it was much more durable than a thermometer with a round casing.

In the years of reconstruction after the war, the SIKA industrial thermometer was increasingly used in plant engineering and was also incorporated into the works standards at many major industrial companies. For this reason, the industry pushed to be independent of a single manufacturer and “persuaded” SIKA to incorporate industrial thermometers with a V-shaped top section in a DIN standard. Hans Siebert (Dipl.-Ing.) called all the competitors together for a standardisation meeting. The standardisation process took 10 years and was completed in 1962.

Both designs (round and V-shaped) continue to be summarised in DIN 16195.

Our mechanical thermometers work according to the expansion principle. In the past, industrial glass thermometers were filled with mercury. Today, a coloured petroleum-based liquid or benzoic acid is used. The level of the liquid in the capillary can be read directly from the glass insert.

In addition to the industrial thermometers from SIKA there are also dial thermometers, which use either the expansion of a gas in their measuring system (nitrogen with 5% helium) or the different thermal expansion coefficients of two metals in a bimetallic coil for the measurement. In dial thermometers, the deflection of the Bourdon tube or the bimetal in the measuring system is transferred mechanically to a pointer movement.

The liquid thread in the capillary rises or falls according to the temperature of the immersion tube. The industrial thermometer measures along the entire installation length l1 and therefore needs to be immersed sufficiently deeply in the medium to be measured. The influence of the ambient temperature is minimised by a large vessel (reservoir for the filling liquid) at the end of the glass insert.

SIKA industrial glass thermometers have a long service life – they can easily last for several decades.

They fulfil the requirements of DIN 16195 and are fully tested during their production. The measuring accuracy of SIKA industrial glass thermometers in accordance with DIN 16195 is guaranteed by SIKA for life (excluding mechanical glass breakage or separation of thermometric column).

They are not subject to ageing or wear and tear, and therefore do not suffer any loss of accuracy. Industrial thermometers do not require external energy and thanks to their modular system are available in several combinations (casing, measuring range, installation length, thread, immersion tube material).

The expansion of a gas in the pressure-constant measuring system of a gas pressure dial thermometer deflects a Bourdon tube in the casing, which in turn instigates a mechanical movement. This changes the position of the pointer.

The influence of the ambient temperature is minimised due to a bimetal compensation spring.

Gas pressure dial thermometers are the only mechanical thermometers that are able to measure at a measuring point several metres away via a capillary tube.

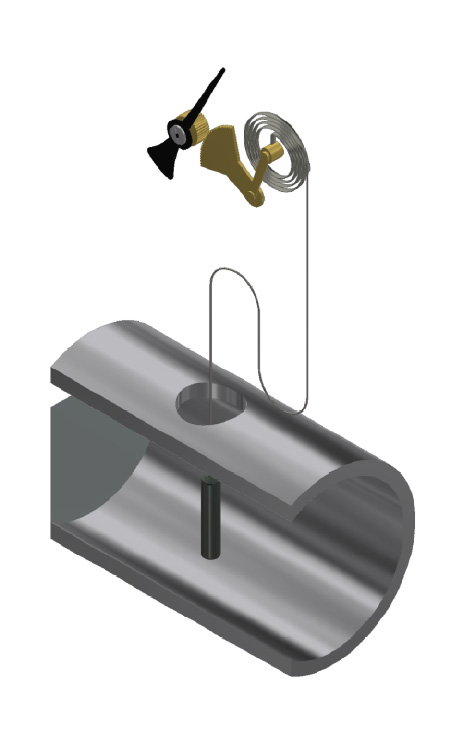

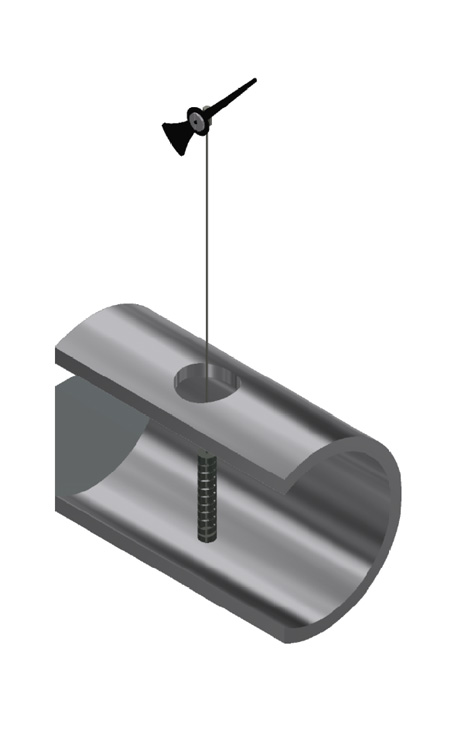

The measuring system comprises a bimetal coil consisting of two interconnected metal strips with different thermal expansion coefficients. The resulting movement (the deflection of the coil) is transmitted directly to a pointer via a shaft or, in angled versions, to the pointer via an angled section.

Due to their measuring principle, bimetal dial thermometers are barely affected by ambient temperatures, as the temperature only influences the behaviour of the bimetal coil.

There are many reasons for the calibration of measuring devices. In various industries, regulations such as ISO 9000, GMP, FDA, SOLAS, DIN apply, which stipulate the regular calibration of electronic temperature measuring devices and temperature sensors. This is intended to ensure the accuracy of the measured values and compliance with the quality standards.

In addition, measuring devices can also show an increasing deviation, also known as drift, over the course of time. This can be caused by various influences, such as vibrations, dropping, chemical substances, changes in temperature and pressure, different operating temperatures, humidity, electromagnetic interference, polarity reversal and short circuits. Regular calibration makes recognising these cases of drift possible and, if required, the implementation of corrections to restore the measuring accuracy.

Industrial thermometers do not suffer from drift. Once they have been set, these thermometers retain their accuracy for a lifetime. The only potential problems are mechanical damage to the glass insert or separation of the thermometric filling. These are visible to the naked eye, though, and can be remedied by replacing the glass insert or rejoining the thread. An invisible, creeping drift as with other measuring principles does not occur in industrial glass thermometers.

The challenges with calibrating industrial thermometers and dial thermometers lie in the specific design of these mechanical measuring devices. In contrast to temperature sensors, which only measure at the tip of the sensor, these thermometers measure along their entire installation length l1 (industrial thermometer) or along the active length of the capillary container (gas filled dial thermometer). This means that the ambient temperature and the radiant heat of the casing also affect parts of the capillary that are not immersed in the medium. These influences are minimised due to the design (e.g. bimetal compensation, ratio of the reservoir of the medium to be measured to the capillary, etc.) and during the adjustment to the accuracy required for the thermometer.

In the case of calibration with a dry block calibrator, the length of the capillary container must be taken into account and the additional measurement uncertainty for the calibration must also be specified. This means that mechanical thermometers could also be calibrated with a dry-block calibrator. However, this requires extensive background knowledge of the resulting measurement uncertainty for different installation lengths l1.

A particular challenge exists with short installation lengths of industrial thermometers (30, 40, 50, 63, 100 mm), as it is almost impossible to reach the homogeneous zone of the calibrator (the lower 40 mm of the calibration insert). In addition, the installation length l1 is measured from the sealing collar, and the thread is part of the installation length. A special calibration insert with a stepped bore is therefore required.

Industrial glass thermometers and dial thermometers undergo several tests during their manufacture to ensure that they comply with the prescribed accuracy levels (DIN 16195 for industrial thermometers and the various classes for dial thermometers). These tests are carried out in crushed ice or water baths, for example.

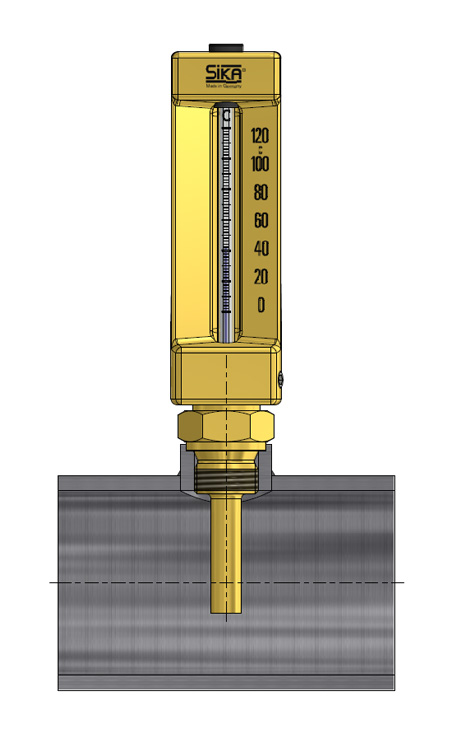

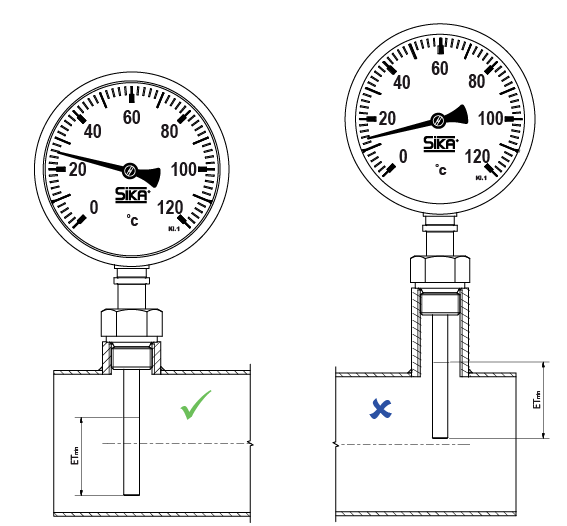

The installation length l1 should be immersed as far into the process as possible to enable an accurate measurement. The installation length is measured from the sealing collar including the thread to the end of the immersion tube. This prevents deviations in the temperature measurement.

Gas filled dial thermometers react sensitively to temperature changes on their casing (additional errors caused by the environment). To minimise the influence of ambient temperatures on the measurement result, the ambient temperature should be kept within the reference temperature (23°C ± 2°C). Gas filled dial thermometers are designed in such a way that the active gas volume (vessel content) is very large compared to the inactive gas volume (capillary tube and measuring element). This minimises the influence of the ambient temperature on the measurement result.

The entire temperature sensor of the gas filled dial thermometer should be immersed in the medium to be measured. It is essential to ensure that the entire length of the expansion vessel ET is completely immersed in the medium.

The temperature on the casing or on the capillary tube of the gas filled dial thermometer with capillary tube should be as close as possible to the reference temperature (23°C ± 2°C), otherwise additional errors can occur.

The longer the capillary tube, the larger the vessel volume must be. Our data sheets contain guideline values for the minimum immersion tube length, the active length ET and the capillary tube length. To minimise the influence of the ambient temperature on the measurement result, it is recommended that the active vessel volume is larger than the inactive gas volume, consisting of the capillary tube and measuring element. If required, dial thermometers can be manufactured in which the vessel volume is specifically tailored to the application.

To prevent falsification of the measurement results, the capillary tube should not be situated close to sources of cold or heat. If the capillary tube is required to pass close to sources of cold or heat, the use of thermal insulation for the capillary tube is advisable.

Bimetal dial thermometers are insensitive to ambient temperatures, as the temperature only affects the bimetal coil. They can be used, transported and stored at a temperature range of -40 to 60°C. With a casing filling, they can be used at a range of -20 to 60°C. Due to their insensitivity to ambient temperatures, bimetal dial thermometers are also suitable for outdoor use, in direct sunlight, for example.

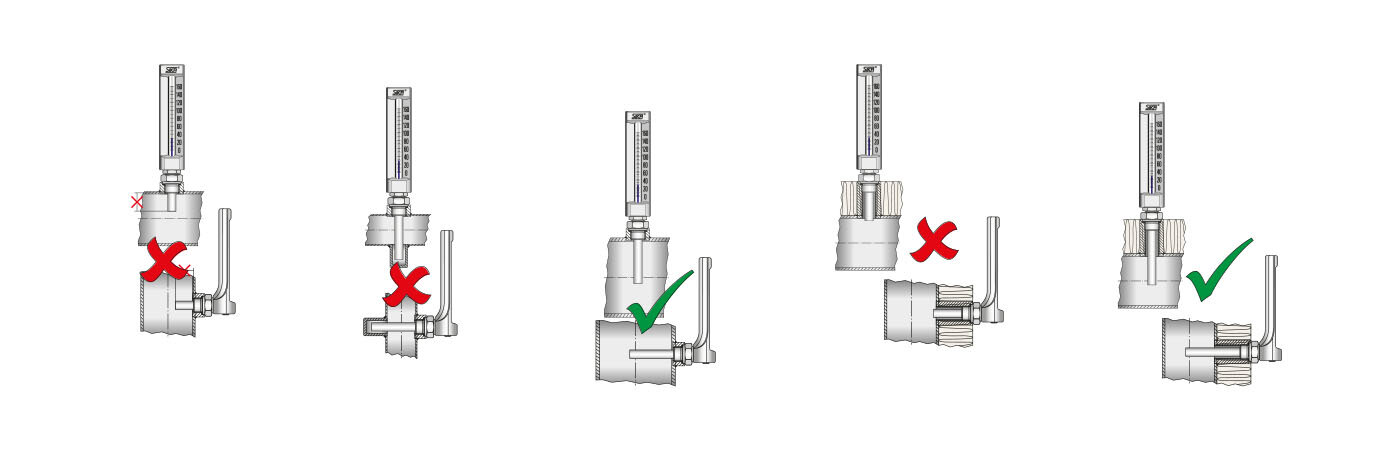

SIKA industrial thermometers must always be installed with their casing pointing vertically upwards to avoid separation of thermometric column. The maximum angle of inclination is 45°.

The installation length l1 must be immersed as deeply as possible into the medium to be measured. In the case of installation in pipelines, the following applies: l1 = min. ½ x x pipe diameter

The immersion tube should always be surrounded by the medium along its entire length; in the case of longer installation lengths, at least 2/3 of the installation length should be surrounded. The adjustment length is always equal to l1.

Additional protection tubes should be used in the case of heavy loads (pressure, temperature, particles).

Dial thermometers must also be installed vertically, especially if they are filled with silicone oil to dampen the pointer movement. The gas reservoir or the bimetal coil (active length) must be surrounded by the medium to be measured, i.e. when installed in a pipeline, the immersion tube must protrude beyond the centre of the pipe.

SIKA industrial thermometers have a very long service life – up to several decades – and their measuring accuracy fulfils the requirements of DIN 16195.

Due to their measuring principle, SIKA industrial thermometers do not drift, as the measuring insert does not contain any wearing parts.

SIKA guarantees the measuring accuracy for a lifetime – with the exception of mechanical glass breakage or separation of thermometric column. In contrast to other mechanical or electronic thermometers, industrial thermometers are not subject to ageing, which means that they do not lose their measuring accuracy.

The situation is somewhat different with dial thermometers, as the movement consists of a large number of parts that are subject to wear, even if the thermometer is filled with silicone oil for damping purposes.

In contrast to electronic thermometers, SIKA industrial thermometers and dial thermometers do not require any external energy.

Even if the power supply fails completely, mechanical thermometers continue to display measured values reliably. This is important in cases where the system operator has to ensure a quick restart in the event of a malfunction or system shut down. In a combined heat and power plant that supplies a community or a hospital, or in the event of a blackout on a ship, for example.

Also, systems are inspected on a routine basis for the detection of minor leaks or smouldering points, for which the use of the human senses continues to be indispensable.

The maintenance and repair personnel use the displays on site, in addition to the electronic displays on the control centre or the laptop.

For safety reasons, mechanical thermometers are installed as a backup in addition to the controllable and adjustable measuring instruments as an on-site display that does not require external energy.

If you do not want to work with two measuring points, we recommend the combination of an industrial thermometer with an additional output signal – our KombiTemp®.