Special production requirements are necessary for a thermometer to know how warm or cold it is. These have been fulfilled by the family-run traditional company SIKA in Kaufungen since 1901, when Carl Siebert and Albert Kühn started producing precision thermometers and technical glass apparatus. Through a variety of innovations and patents for measuring and calibration technology, SIKA has become a global leader in intelligent temperature and flow sensor technology in the domestic, industrial and marine markets with over 370 employees.

For decades, they used mercury for their liquid thermometers made of glass. This had already been introduced in 1720 by Daniel G. Fahrenheit with the first usable thermometer. The heavy metal is particularly suitable because it is easy to read on the scale, does not moisten the glass and reacts quickly to temperature changes. If, in addition, nitrogen is injected at a pressure of 16 bar in a final production step after the mercury has been filled in and the glass capillaries are fused at the same time, values up to 750 °C can be read on the scale. This requires a special electrical pressure filling apparatus, which must be operated manually for each thermometer. However, mercury is highly toxic in its vapor state and when absorbed through respiration. This also applies to many chemical mercury compounds that are soluble in water. Therefore, the marketing of liquid thermometers containing mercury has been banned in the EU since 2014, and the use of the pressure filling apparatus will end in 2018 after 78 years of use at SIKA.

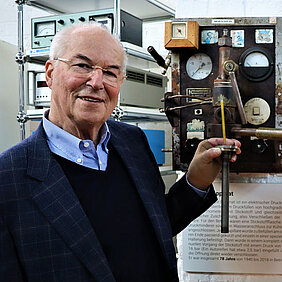

"We are very pleased to now be able to exhibit the apparatus in the Museum of Technology, thus giving the manufacture of precision measuring instruments a worthy place in the history of technology in North Hesse," says honorary chairman Ewald Griesel, who established contact with SIKA. The newly opened exhibition area in the TMK uses historical pictures to present the regional production of glass thermometers, which are still mainly manufactured by hand. Instead of mercury, SIKA now uses blue-dyed petroleum, which can be used to measure temperatures of up to 250 °C. In order to be able to produce precise and reliable measuring instruments, numerous work steps are necessary, which require the highest concentration and accuracy. This is illustrated by tools such as glass knives for carving and squeezing tongs for precisely deforming glass capillaries in the Technology Museum. With their developments, innovations and family business, the former managing directors Christian and Werner Siebert have written an important piece of industrial history in northern Hesse, which can now be experienced in the Technology Museum. "Our connection to the region is already clear in our name SIKA, which is composed of the two initial letters of the founding name Siebert and the founding location Kassel, respectively. In order to tell the technical achievements of SIKA in a museum-like way, the TMK is exactly the right place", the two conclude.

Source: Thomas Siemon, (2023, 18. April). Dieses Thermometer verkraftet 750 Grad. HNA. Gedruckte Ausgabe. https://www.hna.de/

Photos: Andreas Fischer