Interesting Facts About Anodizing

In our anodizing plant, we process a large number of parts for our products. What is anodizing, though?

Anodizing actually refers to the electrolytic oxidation of aluminium. During an electrolytic process, a layer of oxide is produced on the surface of a work-piece that is made from aluminium. This doesn’t mean that the metal is coated with a layer of a different material, but that a protective coating is formed in the uppermost metal layer. As long as it is gap-free, this coating protects the aluminium against further corrosion.

In principle, the process of oxidation would also occur by itself when the work-piece comes into contact with the oxygen in the air. During the anodizing process, however, this natural layer of oxide is created far more quickly, and on a targeted basis.

The anodized layer contains micro-pores which can absorb dye and are sealed through subsequent sealing. The hue applied in this way is connected firmly with the work-piece and can only be removed with great difficulty.

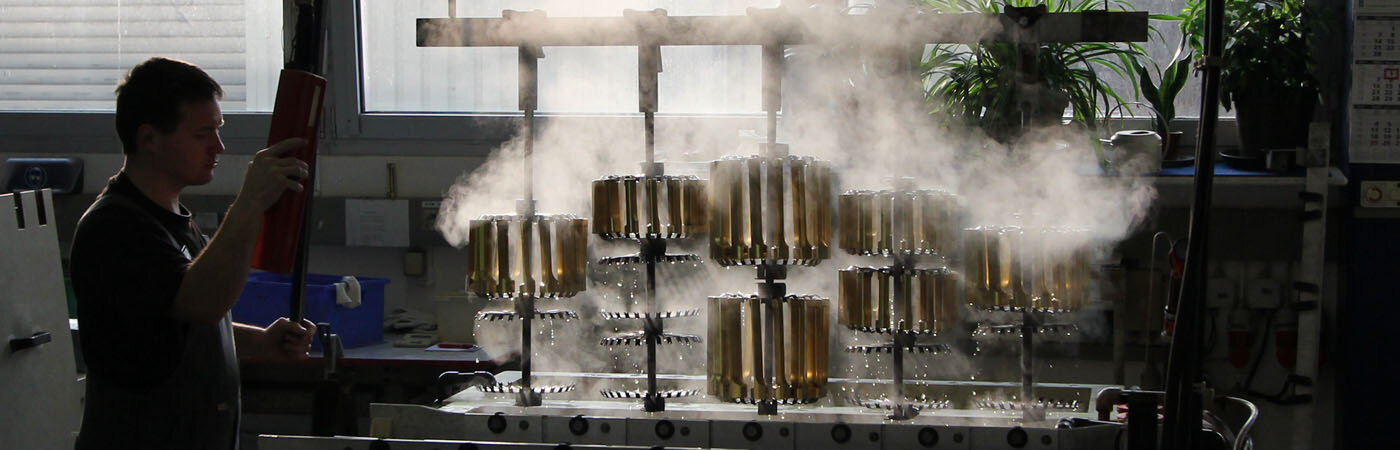

We use the anodizing process to dye our casings for industrial thermometers in gold, for example. We also apply the logo and scale to the casings before the final sealing of the surface. After the sealing, the dye and inscription are located within the anodized layer. The casings of our pressure pumps and other aluminium parts for our production division are also anodized.

Aluminium parts can be pretreated. This means that if necessary, the work-pieces are smoothly sanded in our vibratory grinding system, before being degreased and pickled. The pickling removes the thin natural layer of oxide. The anodizing, dyeing, printing and sealing are then carried out in a water bath.

Taking the example of the casing for the industrial thermometer, the process is as follows:

A “de-anodized” anodized casing is also possible. In this case, the anodized layer is removed again, although not mechanically but using prolonged pickling. The process corresponds to the pickling or the removal of the natural anodized layer in preparation for the anodizing.