How Does a Magnetic Inductive Flow Sensor Work?

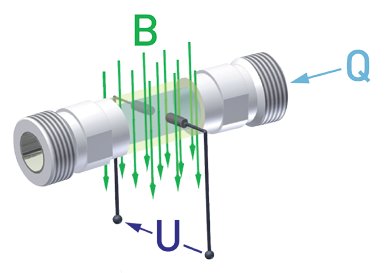

The magnetic inductive flow sensor operates according to the induction principle, i.e. a direct voltage is generated through the movement of a conductor in a magnetic field.

The measurement principle is based on the work of English physicist Michael Faraday and his eponymous law of induction. According to the law of induction, a force acts on electric charge carriers when they move through a magnetic field, so that a voltage is induced transversely to the direction of movement. This effect is also known as the “Hall effect”.

The measuring pipe of the flow sensor is surrounded by a magnetic field (B). An electrically-conductive liquid (Q) flows through the measuring pipe. The positive and negative charge carriers are deflected in the opposite direction. A voltage perpendicular to the magnetic field is produced, which is picked up by the two electrodes. The induced voltage is proportional to the average flow velocity of the liquid.

A parasitic effect is that in addition to the useful signal, an interference voltage occurs due to electrochemical disturbances, which is referred to as the electrode chemistry. This effect can be compensated for with the use of a clocked constant field. This means that the magnetic field of the coil is continuously reversed, so that the useful signal constantly changes its polarity but the interference signal does not. In this way, useful signals and disturbances can be distinguished from each another and the measuring accuracy can be improved.

The magnetic inductive flow sensors allow for the flow / volumetric flow measurement or dosing of electrically-conductive liquids without moving parts. These are the ideal flow sensors in terms of accuracy and reliability.

Advantages of magnetic-inductive flow sensors:

Do you know about our magnetic inductive flow sensors in the VMI, VMZ and VMM series?

The induQ VMI is a compact flow sensor which is used in dosing applications. With its EU-RO approval, it is suitable for exhaust gas purification on ships with urea injection.

The induQ VMZ stands out with its reasonable price and is suitable for series use in machine and plant construction as well as for mobile applications.

The induQ VMM is a process flow meter that can be found in large heat pumps and in water and waste water applications, for example.