Accuracy Classes of Resistance Thermometers and Thermocouples

In our temperature sensor data sheets, you always find information regarding the accuracy of the temperature sensor. But which accuracy classes are distinguished between?

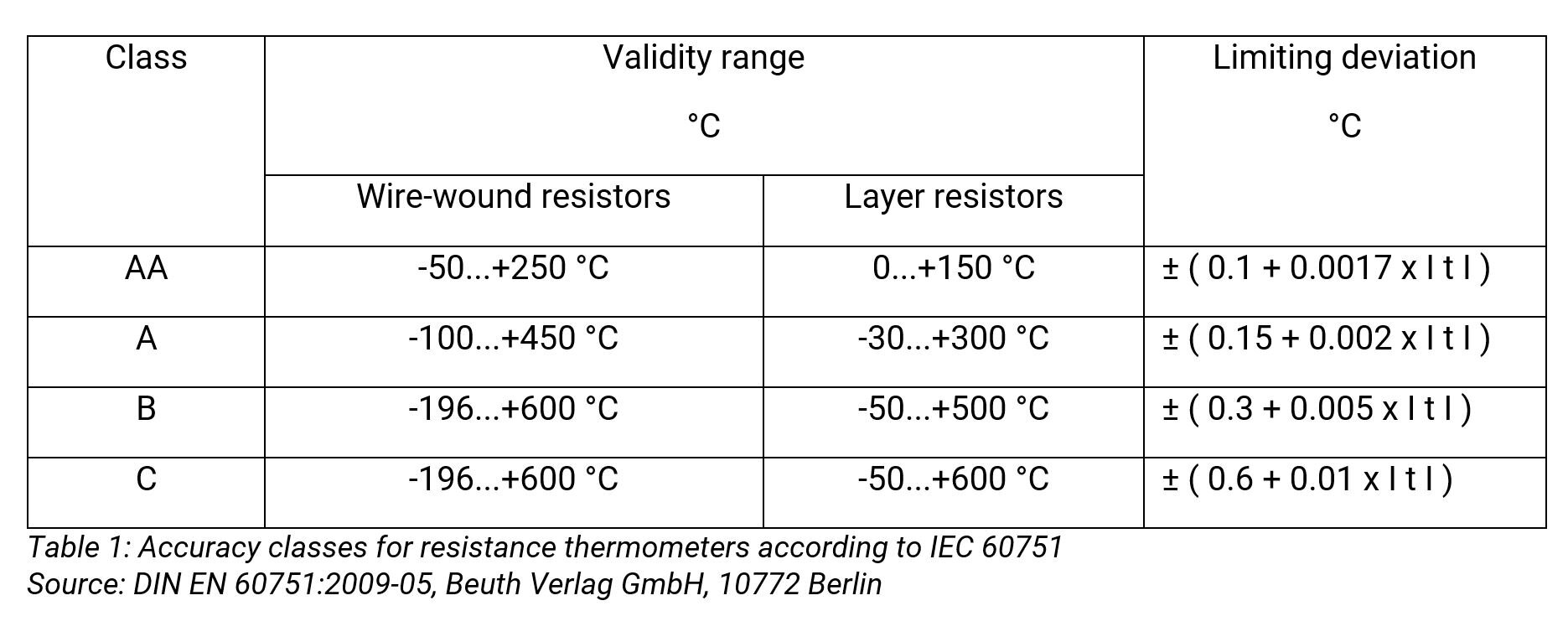

For temperature sensors with a Pt100 or Pt1000 sensor element, according to DIN EN 60751, four different accuracy classes are distinguished between; class AA, A, B and C.

Temperature sensors with the accuracy class AA are the temperature sensors with the lowest limit deviation and are the “most accurate”. The validity range indicates the range in which the deviation is defined according to the standard. With most of the temperature sensors from SIKA, class B layer resistors are installed as standard.

Example: At a temperature of 120 °C measured using a temperature sensor with accuracy class B, an error of ± 0.9 K results.

The accuracy classes do not apply to all resistance thermometers, though. In this case, the accuracy classes are usually specified in the respective data sheet according to the manufacturer and type.

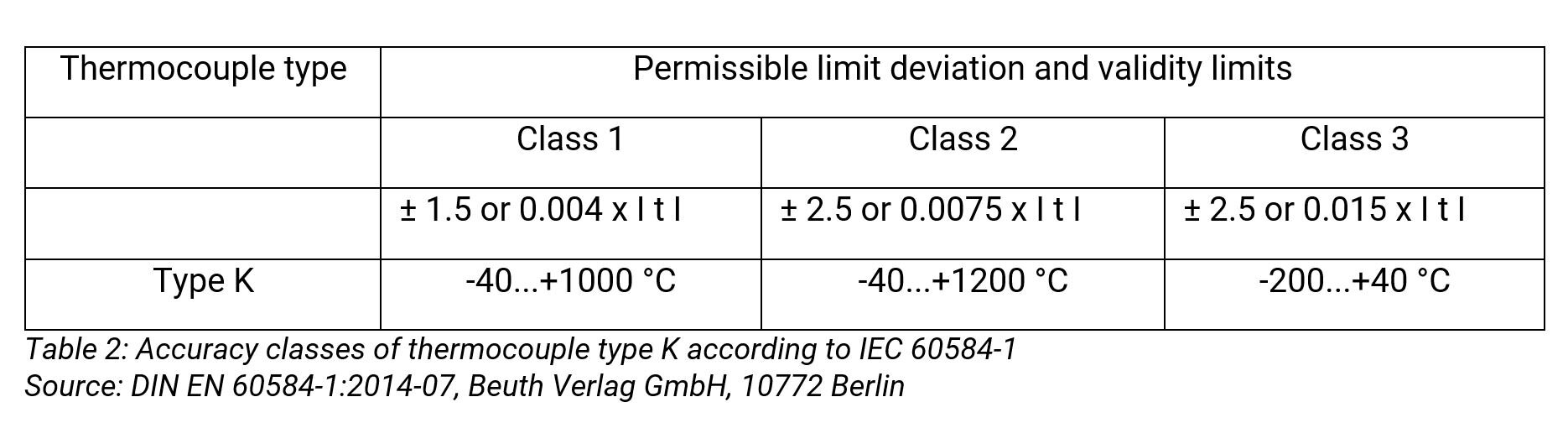

According to DIN EN 60584-1, temperature sensors with a thermocouple are divided into three different accuracy classes; classes 1, 2 and 3.

The error limits resulting from the accuracy class depend on the type of thermocouple which is installed. Most SIKA temperature sensors are equipped with type K thermocouples.

Temperature sensors with the accuracy class 1 are the temperature sensors with the lowest limit deviation and the “most accurate”. The validity range indicates the range in which the deviation is defined according to the standard. Most SIKA temperature sensors are equipped with class 1 thermocouples as standard.

Example: At a temperature of 450 °C measured using a temperature sensor with accuracy class 1, an error of ± 1.8 K results.

Please bear in mind that the calculated error only relates to the temperature sensor itself. The error caused by cables, connections or measuring devices is not taken into account. An error of this kind is referred to as a “measuring chain” error. In this respect, the errors of all the components in the “measuring chain” are taken into account.

This essentially depends on how precisely the temperature in your process or in the control loop has to be measured. The requirements surrounding the accuracy of the temperature sensor during autoclaving are especially high in the fields of medical and food technology, for example.

For this purpose, SIKA offers specially-designed temperature sensors that fulfil the requirements surrounding accuracy and reliability: Temperature sensor in marine configuration, temperature sensor in HVAC configuration and temperature sensor in industrial configuration with IO link.